Our Products

03a

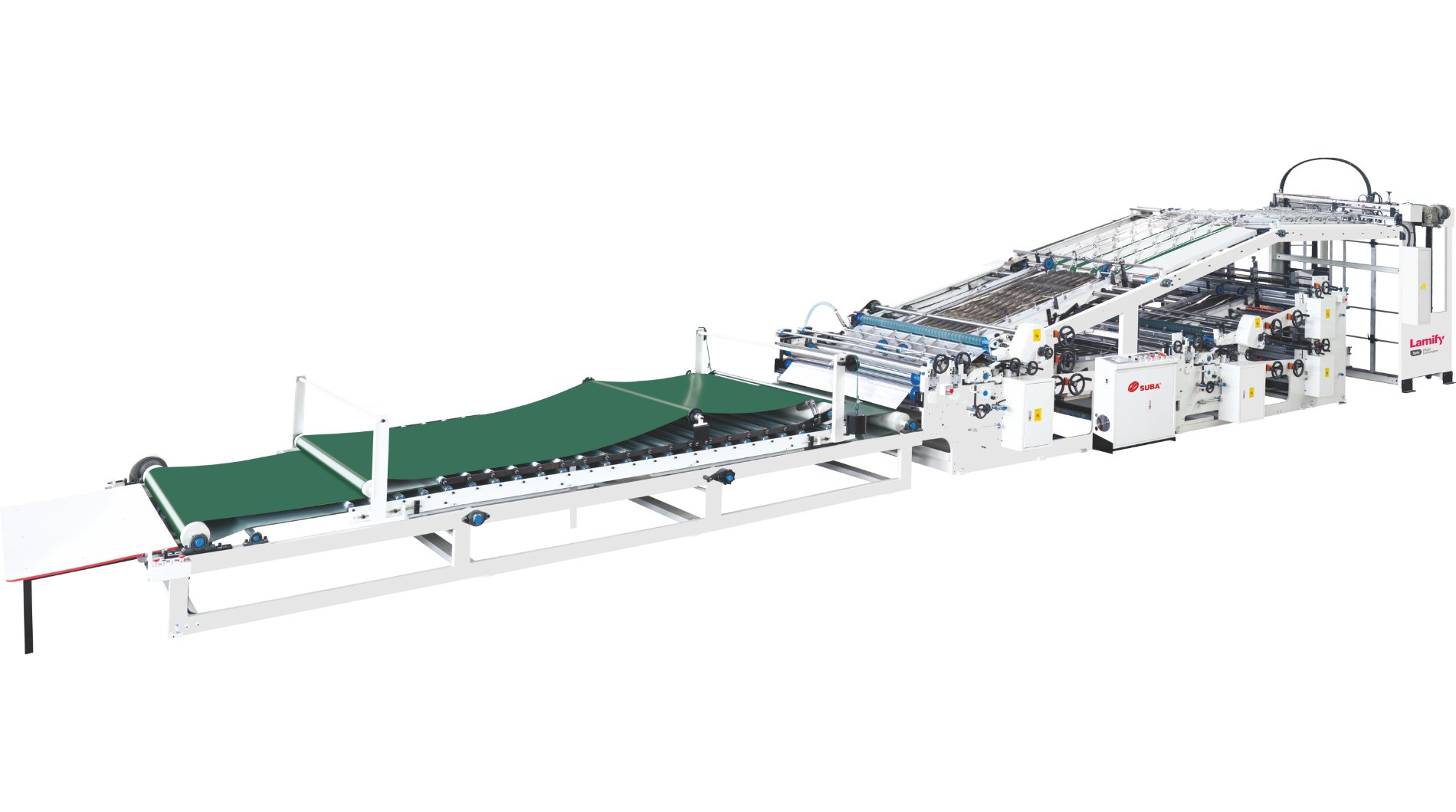

Automatic 5Ply Flute Laminator

- Suitable for Flute laminated sheets 3ply / 5ply in single pass.

- Can handle top sheet 150 gsm.

- Fastest pay back.

- Several installations across India.

- Good quality 5ply boxes without investment on 5ply plant.

- Very suitable for 5ply box production.

- Max. speed of 3500 sheets per hour for 5ply

- Max. speed of 4500 sheets per hour for 3ply

Main Features :

- Three-Feeder Automatic Flute Laminator is fortified model adopting two bottom feeders and one top feeder, especially suitable for laminating two single flutes into 4 ply corrugated boards, also acting as a regular flute laminator to transfer thicker and large-sized boards smoothly and freely, operator friendly.

- Three-Feeder Automatic Flute Laminator is applied in broad scope of papers, substrate papers from cardboards, corrugated paperboards, single layer corrugated boards which can be laminated easily and accurately, and total boards from 2 bottom feeders are maximum 4 layers.

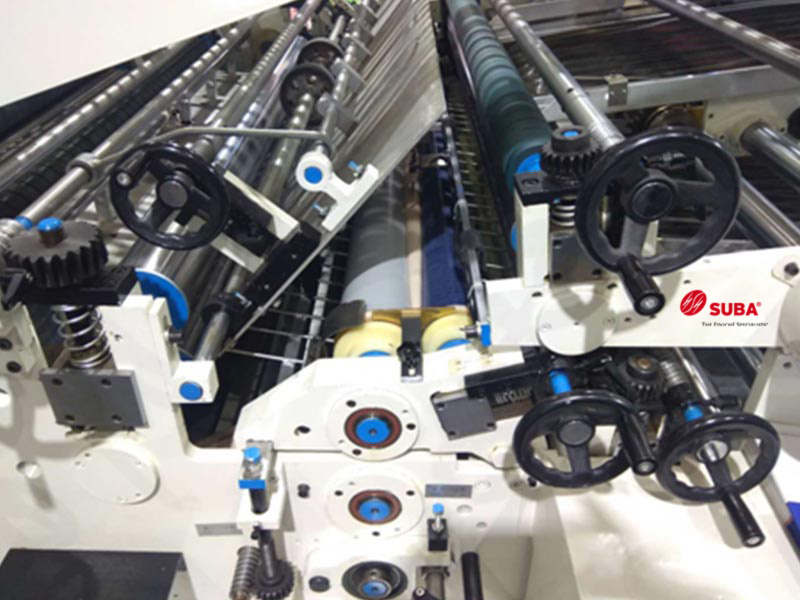

Top Sheet Servo Feeder :

- Equipped with 4 paper raising caps and 4 feeding caps to ensure smooth feeding.

- Paper pressing base with air blower and two sides sub-blower for wider paper.

Two Bottom Sheet Feeder :

- The corrugated paper is attached and goes through the Spring plates by suction belt and make the corrugated board delivery smoothly with side registration.

- Bottom sheet suction controlled by electro magnetic valve.

Alignment and Timing System

- Synchronous Register Chains (Imported from Taiwan).Timing is designed by synchronous pushing claw that makes accurate registration. There are buffer designed before pushing claw striking the paper that prevent paper edge from damage. Front register adjusted.

- Side register adapts entire column spring plates to guarantee laminating accuracy at full running time and at high running speed.

Gluing System :

- The adjustable glue roller system applies evenly on the corrugated board. The stainless steel glueroller saves glue consumption with three sensors to prevent overflow. This recycles gluing system which refills the glue in the slot at both gluing rollers by side supporters. The gluing system prevents glue wasting for better performance of lamination.

Electrical Control System :

- Operator Panel shows all operation buttons and functions. Auxiliary Operator Panels are located in the Feeder and Pressing Conveyor. The Counter calculates laminating sheets through photocell control and Fixed Speed Device ensures fixed running speed.

- Electrical driven systems are Schneider and Fotek & Anly from Taiwan.

Automatic 5Ply Flute Laminator

| Technical Specifications | |||

|---|---|---|---|

| Model | Lamify 5ply 1450 | Lamify 5ply 1650 | |

| Max.Sheet Size(L x W, mm) | 1450 x 1450 | 1650 x 1450 | |

| Min. Sheet Size (L*W, mm) | 450 x 420 | ||

| Thickness | Top | 180 ~ 800 gsm cardboard | |

| Middle | 0.5-1mm (Board) / A~N Flute (2ply) | ||

| Bottom | 0.5-1mm (Board) / A~N Flute (2 ply) | ||

| Accuracy (Subject to Paper Quality and Specifications) |

±1.5mm | ||

| Maximum Speed (Subject to Paper Quality and Specifications) | 5Ply | 3500 sheets / hour | |

| 3Ply | 4500 sheets / hour | ||

| Power | AC~380V ( 21 Kw) | ||

| Dimension: L X W X H(M) | 16549 x 2900 x 2900mm | 16549 x 3100 x 2900mm | |

| Dimensions with working space: L*W*H | 19500 x 4900 x 3500mm | 19500 x 5100 x 3500mm | |

| Weight (KG) | 10500 Kgs | 11000 Kgs | |

*Note: Specifications are subject to change without notice.